|

| Circular economy is a current trend... |

| The development of economies comes with an increase in the number of resources utilized by countries, leading resources to eventually deplete and the quality of human life to suffer. As a result, most countries are changing to a circular economy model, with environmentally friendly manufacturing methods that restore, regenerate, and gradually reduce the amount of resources that must be exploited while also limiting emissions into the environment. For instance, with the rapid growth due to the economic reform since 1970, China has been facing pollution, waste generation, and resource depletion. According to data in 2015, China produced 46% of the world's aluminum, 60% of cement, and 50% of steel, while consuming more raw resources than the other 35 countries in the OECD (Organization for Economic Cooperation and Development) combined. China has utilized up to 2.5 kilograms of raw materials to produce one USD of GDP, whereas OECD countries use only 0.54 kg. The strong development of heavy industries, along with inefficient resource usage, is driving China's adoption of a circular economy model to ensure sustainable growth. On the other hand, Europe is more reliant on imported resources than any other region in the globe, with almost 40% of resources used coming from outside the continent. Therefore, the circular economy is a solution to the growing reliance on imports while also reducing environmental pressures. |

|

| Dr. Nguyen Hoa Cuong, Deputy Director of the Central Institute for Economic Management, pointed out in his book "Circular Economy & Pioneering Models," which was published on September 21, that due to the urgency of implementing the circular economy model, national and regional governments have taken drastic measures. In particular, Europe has developed an action plan to support the transition process, promote material loop closure, and govern product life cycles. In addition, Europe has framework directives on waste and indicators for monitoring the circular economy. In Sweden, there has been not only a general recycling and garbage collection strategy, but also a policy to establish a circular economy by plastics, manufacturing, building, and consumption industries. China has also issued the Law on Circular Economy Promotion, which is regarded as a significant approach to economic and social growth, boosting resource efficiency, environmental protection, and long-term development. China's "five-year" plans have highlighted the country's policy shift toward heavy industrial resource recycling, which includes replacing prior models and implementing resource efficiency. Simultaneously, this country has announced management strategies to improve environmental quality and accelerate environmental damage rehabilitation. Furthermore, the success of circular economy models requires the engagement of enterprises. According to David Riddle, CEO of Tan Hiep Phat and co-author of the book “Circular Economy & Pioneering Models”, many corporations around the world are actively transitioning from the traditional linear economy to a sustainable circular economy because this model brings many benefits to society and businesses themselves. As a result of process innovation initiatives and sparking creativity, the circular economy helps businesses increase corporate efficiency. This model can also provide a competitive advantage for businesses that adopt it, as large business partners are increasingly imposing strict sustainability requirements. Furthermore, the public is becoming more aware of environmental protection and is more in favor of "green" brands. Many Vietnamese companies have begun to use this model in their business development strategies. |

| …but reaching a sustainable circular economy is not a walk in the park |

| However, a circular economy is a systematic approach, requiring the participation and close coordination of actors in the economy. Therefore, besides favorable factors, Vietnam also encounters many problems in institutions, policies, infrastructure, science, technology, operating mechanisms, and markets.

For example, in the field of plastic waste recycling, according to Le Xuan Dong, managing director of the Market Research and Consulting Division of FiinGroup, there are three major challenges. One is operational challenges, when the amount of plastic waste collected is not commensurate with the design capacity, due to the lack of a system for classifying and collecting plastic waste at source as well as regulations that do not exist in Vietnam. Second, the output demand for recycled plastic resins is not sustainable. Only a few beverage and food manufacturing enterprises made commitments. Most importantly, investment costs for the circular economy model are not low, and Vietnamese businesses, mainly small and medium enterprises, still face many difficulties in accessing preferential green credit. During the publication launch, David Riddle said “Achieving a sustainable circular economy is not an easy task. Even highly developed economies like Singapore had to reconsider how countries can successfully protect their environment, and resources and achieve circularity.” However, he also said that businesses can implement circular economy measures that are important for the environment and still reap significant business benefits. David Riddle made some suggestions for cooperation between the parties. One of the most important initiatives that require collaboration is educating citizens about why developing and implementing circular economy measures is so important. This process can take time and require a change in thinking over many generations. Another approach is that of Boots, in which an economic incentive is given to encourage recycling. Hong Kong (China) created measures to discourage consumers from using excess plastic, such as a plastic bag tax that applies to all plastic shopping bags in the city. “Think of recycled plastic as a new raw material for a successful industry. This will cement Vietnam as a greener country, and create hundreds of thousands, perhaps even millions, of new jobs. Globally, we have the technology to make creating and using recycled plastic a reality,” said David Riddle. The challenge for this, according to David Riddle, lies in having the right infrastructure to do this at scale. Once again, this is why cooperation on an unprecedented scale is necessary and urgent. Tan Hiep Phat believes that it is time for businesses to truly participate. Businesses need a strong legal corridor, specifying responsibilities for manufacturers and distributors regarding waste recovery, classification and recycling, or payment of waste management costs for discarded products.

Sharing the same opinion as the representative of Tan Hiep Phat, Nguyen Si Dung, former Vice Chairman of the Office of the National Assembly said that the issue of “reverse incentives” is currently a big challenge. Nguyen Si Dung took the example of textbook products. If students in the previous class leave the books for students in the next class, demand cannot increase. Production of books is designed so that they can only be used once because if they are used many times, they cannot be sold anymore. “If we want a circular economy, all policies must eliminate that ‘reverse incentive.’ The important thing is how to make recycled products, which belong to the circular economy, more profitable. As tools, the state already has communications and a tax mechanism,” Dung said. “As the CEO of Tan Hiep Phat said, the state has to design a relatively sophisticated tax system. I think that's important. Along with that, the system of procedures and utilization of original materials must be tighter, and recycling materials must be easier.” |

| Effort and persistence are required in circular economy transition |

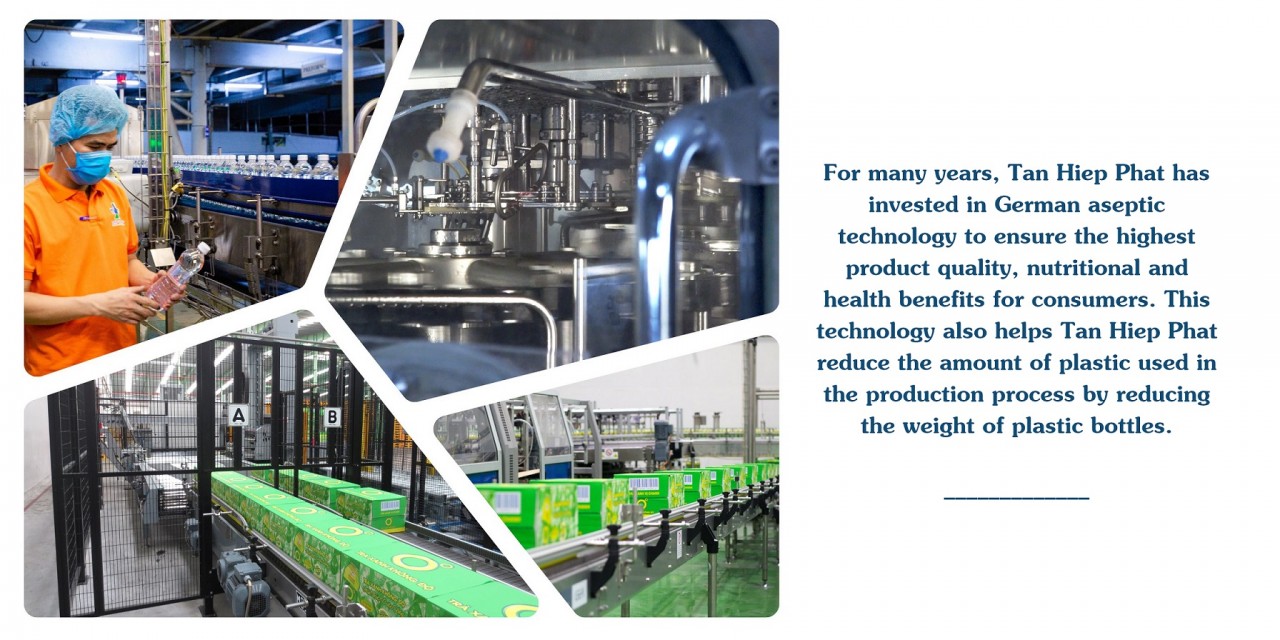

| Recognizing the importance of circular economy to ensure the community's sustainable development and the society's long-term benefits, many businesses have pioneered in applying the model and dared to face many difficulties. Overcoming all challenges with persistent efforts, they have achieved positive results. Tan Hiep Phat Group is a typical example in the beverage production segment with the process of transforming its business model and developing a circular economy with the 3R strategy (Reducing waste - Reducing waste, Reusing, Recycling) since 2013. 3R is a circular economy model that has been successful in many developed countries, including Sweden - the world's leading economy. During the recycling revolution that has been running for the past two decades, the proportion of Swedish households recycling waste has increased from 38% in 1975 to 99% today, and only 1% of waste is sent to landfill. A lot of waste is recycled and used for various purposes such as biogas and energy. According to David Riddle, regarding Tan Hiep Phat, it can be said that the company's initial success in shifting towards a circular economy is the significant reduction in the amount of plastic used in its beverage bottles. For many years, Tan Hiep Phat has invested in German aseptic technology to ensure the highest product quality, nutritional and health benefits for consumers. This technology also helps Tan Hiep Phat reduce the amount of plastic used in the production process by reducing the weight of plastic bottles. |

|

| 10 years ago, Tan Hiep Phat implemented a bottle-lightening project in which the weight of each bottle was reduced by nearly 20%. At the same time, due to its investment in aseptic technology, the group can also reduce losses in the production process and decrease both electricity and water usage. Five years later, Tan Hiep Phat was able to further reduce bottle weight, along with reducing plastic waste by 34,000 tons. In the next four years, to 2023, the reduction reaches 44,000 tons, making a total of 78,000 tons of plastic waste eliminated over the nine-year period. Other important measures at Tan Hiep Phat to date include recycling and reusing shrink wrap and plastic bags produced by the company to make multi-purpose bags for holding blanks and lids and eliminating the use of cardboard boxes by replacing them with shrink wrap made from recycled plastic. Since 2021, Tan Hiep Phat has been operating a plastic recycling line with a focus on producing pellet pallets from waste plastic for Tan Hiep Phat to use. In the future, it will be supplied to other companies that want to replace their production inputs with recycled materials. “Vietnam is famous for its beautiful beaches and sunny coastlines. We must act now to conserve marine life and preserve our beaches and our hidden tourism gems. We must work together to limit single-use plastic to the highest possibility. Tan Hiep Phat is willing to cooperate to solve the challenges ahead and do everything possible to achieve a sustainable circular economy," said David Riddle when concluding his speech. |

| _____________ VietnamTimes reporters |