India is set to become a global semiconductor powerhouse by 2035

|

India aims to become a key global semiconductor hub within a decade by investing in infrastructure and technical expertise. With over 90% of semiconductors currently imported, building a domestic ecosystem is essential. The government’s $10 billion incentive program, covering up to 50% of project costs, is attracting global players. However, success will hinge on improving logistics, utilities, customs processes, and developing a skilled workforce to foster a manufacturing-friendly environment.

Speaking exclusively to ET EDGE INSIGHTS, Srini Chinamilli, Co-Founder & CEO, Tessolve delves into India’s ambitious semiconductor mission i.e. India Semiconductor Mission, global partnerships, building a skilled workforce for advanced semiconductor chips development, opportunities for the industry players and much more. He stated, “With focused investments in infrastructure, policy implementation, and talent development, India is on track to become a competitive global semiconductor hub within the next decade.”

What are the main challenges that India faces in building a competitive semiconductor industry, and how can these be addressed?

I view the current landscape not as a challenge, but as a significant opportunity for India to build a competitive semiconductor industry. One of the most exciting opportunities lies in the establishment of semiconductor fabs, with large investments coming from both the government and major conglomerates. The government’s incentive programs, including the India Semiconductor Mission (ISM), are driving this growth, creating a favorable environment for semiconductor manufacturing in India.

Another huge opportunity is for India-based semiconductor product companies catering to domestic and international demand for chips. Indian engineers have been helping multinational companies design cutting-edge products. Why not do this for homegrown companies?

Another key opportunity is in technology. Through partnerships with global semiconductor powerhouses, India is positioned to access the latest advancements and foster innovation. Equally important, though often underappreciated, is the availability of specialized talent. At Tessolve, we focus on nurturing talent from tier-2 and tier-3 cities, training them in the most advanced semiconductor technologies, and preparing them for the future. The ISM and government skill development programs are steps in the right direction, but further emphasis on skill development in emerging technologies like semiconductors would accelerate our progress. With continued efforts, India is well on its way to becoming a global semiconductor hub.

How can India’s partnerships with countries like the U.S., Japan, and Taiwan help accelerate its semiconductor goals?

India’s partnerships with other countries are pivotal in fast-tracking its semiconductor goals by leveraging its technological expertise, investment potential, and advanced manufacturing capabilities. Collaborations with Taiwan (China) bring cutting-edge assembly and fabrication technologies, while the U.S. contributes its leadership in semiconductor design and innovation. Japan’s strengths in semiconductor materials and precision engineering further complement India’s efforts to build a robust ecosystem. This helps in the global ecosystem as well. When the world is moving towards a China Plus One strategy, India becomes an alternative.

These partnerships are not only fostering technology transfer and strategic investments but are also strengthening India’s integration into the global semiconductor supply chain. By addressing critical challenges such as infrastructure, logistics, and workforce development, and supported by the government’s $10 billion incentive scheme, India is poised to emerge as a competitive global hub for semiconductors in the coming decade.

How can initiatives like the India Semiconductor Mission (ISM) ensure that public-private collaborations deliver long-term results rather than short-term gains?

For an industry as capital-intensive and technology-driven as semiconductors, a little handholding from the government is essential to get started. The India Semiconductor Mission (ISM) has provided that much-needed impetus, laying out a clear roadmap and incentivizing companies with a long-term focus. Its emphasis on capital expenditure support, specialized infrastructure, and talent development is set to deliver lasting benefits to India’s semiconductor economy.

For the first time in India’s history, we are witnessing a collective seriousness from both the central and state governments, along with large private conglomerates, to make India self-reliant in semiconductors. These are early days, but the trajectory is promising. I am more confident than ever about India’s semiconductor story and its potential to emerge as a global leader in this critical sector.

What role can public-private partnerships play in building a workforce capable of developing advanced semiconductor chips?

We congratulate the government for its visionary efforts over the past few budgets in addressing the critical skill gaps in India’s semiconductor industry. The India Semiconductor Mission (ISM) has laid the groundwork for skill development, and the most recent budget has gone the extra mile by fostering a collaborative approach between governments and industry partners. With India boasting the largest young population, this initiative is poised to equip the youth with the knowledge and skills required to excel in this field. At Tessolve, we have been quietly and consistently training engineers in the design and testing of advanced semiconductor chips, long before semiconductors became a buzzword. While there is still more to be done, we remain confident in our direction and focused on building a workforce ready to contribute to India’s semiconductor future.

What opportunities does Tessolve foresee in India’s ambitious semiconductor mission? How is it leveraging its know-how into the same?

With significant opportunities presented by India’s ambitious semiconductor opportunities, Tessolve is well-positioned to play a critical role in its success. We have been in India for over 20 years and made considerable investments to provide world-class solutions to leading semiconductor companies in the world. We are now excited about helping homegrown companies. Through our end-to-end engineering expertise in chip design, testing, and productization, we have robust capabilities to support the nation’s massive semiconductor ecosystem dreams.

India now boasts over 125,000 chip designers, contributing approximately 20% of the global workforce, and we are capitalizing on this growth. Having invested in developing the country’s semiconductor ecosystem since 2004, we have built world-class engineering teams in India, serving customers in the U.S., Europe, and beyond. Currently, we operate across 10 cities in India and trained over 6,000 engineers from the ground up, addressing the critical need for skilled talent in the industry.

For us, enabling manufacturing through engineering solutions is a focal point as India transitions from a design-centric industry to full-scale chip production. Through our expertise in chip design and productization, we are well-positioned to support these companies in accelerating their product designs to market.

How realistic is India’s target of becoming a global semiconductor hub in the next decade, given the current state of infrastructure and technical expertise?

India’s ambition to become a global semiconductor hub within the next decade is bold but achievable. With a clear focus on infrastructure development and leveraging its expanding technical expertise, India has the potential to transform into a significant player in the global semiconductor ecosystem. Currently, over 90% of semiconductors are imported, making it crucial to build a robust domestic ecosystem.

The government’s $10 billion incentive program, offering up to 50% of project costs, has provided impetus in attracting global and domestic players to set up manufacturing and assembly facilities. However, achieving this goal will require sustained improvements in transportation, power, water availability, streamlined customs processes, and most importantly skilled resource availability to create a manufacturing-friendly environment.

With concerted efforts in infrastructure, policy execution, and talent development, India is well-positioned to emerge as a competitive global semiconductor hub within the next decade.

Recommended

World

World

Pakistan NCRC report explores emerging child rights issues

World

World

"India has right to defend herself against terror," says German Foreign Minister, endorses Op Sindoor

World

World

‘We stand with India’: Japan, UAE back New Delhi over its global outreach against terror

World

World

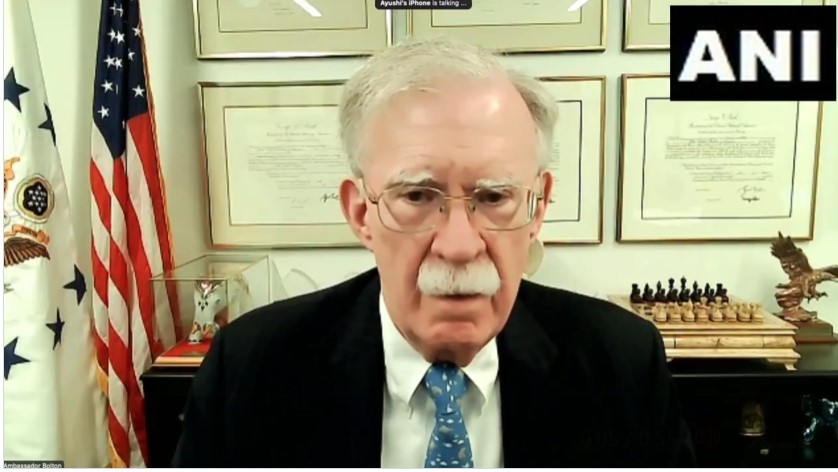

'Action Was Entirely Justifiable': Former US NSA John Bolton Backs India's Right After Pahalgam Attack

World

World

US, China Conclude Trade Talks with Positive Outcome

World

World

Nifty, Sensex jumped more than 2% in opening as India-Pakistan tensions ease

World

World

Easing of US-China Tariffs: Markets React Positively, Experts Remain Cautious

World

World