Japan, Vietnam further cooperate on rubber industry

In Hanoi, on March 3rd, researchers of ESCANBER project disseminate their research outcomes at a symposium to further application of the results of their research to the public sphere.

The symposium is the world’s 4th largest symposium on natural rubber, and is considered an extraordinarily valuable event for the rubber industry in Vietnam to expand their business and introduce new products to the market.

More than 20 researchers from Hanoi University of Science and Technology (HUST) and Nagaoka University of Technology and Science (NUT) along with representatives of rubber manufacturing companies from Vietnam and Japan participate in the symposium.

A panel of world leading researchers from Japan and Vietnam discuss future development of the rubber industry in Vietnam and the world.

The ESCANBER “Establishment of Carbon-Cycle-System with Natural Rubber” project is the collaboration among HUST, NUT and Rubber Research Institute of Vietnam (RRIV), funded by Japanese ODA through Japan International Cooperation Agency (JICA) and Japan Science and Technology Agency (JST). It started in April 2011 and will be completed at the end of March 2016.

The new technology developed within the scope of the Project increases the safety of rubber products and promotes uses of natural rubber to replace synthetic rubber. Using low-protein rubber provided by the project, some rubber factories around Ho Chi Minh city have produced trial pieces of laboratory gloves, surgical gloves and kitchen gloves. The project distributed 150,000 pairs of trial laboratory gloves to 16 major hospitals and research institutes in Hanoi to get their feedback. A nurse who used the trial gloves commented, “If those gloves are cost-effective enough, we’ll be able to purchase them and reduce allergic reactions of patients and medical workers.”

Besides, a high-performance rubber and an advanced polymer with high conductivity have been developed from protein-free natural rubber within the scope of the project. These materials may be useful for the automotive industry or particular applications such as polymer electrolyte membranes in fuel cells.

As one of the outputs, the project has also successfully developed advanced treatment technology of wastewater from rubber processing factories, which efficiently reduces greenhouse gas emissions and recovers methane as an energy resource. It also developed enzymes to decompose cellulosic biomass with rubber to produce sugar and alcohol.

“The project has produced critical outcomes which will promote substituting carbon-neutral natural rubber for synthetic rubber made from fossil resources and contribute to reduction of greenhouse gases. As rubber production in Vietnam has been growing rapidly in recent years, development of new natural rubber products will also contribute to Green Development in Vietnam”, said Prof. Fukuda, project leader, who has been one of the pioneer researchers in developing advanced technologies for the project./.

( VNF )

Recommended

National

National

Four Notable Outcomes of General Secretary To Lam’s Four-nation Tour

National

National

Vietnam News Today (May 15): Vietnam Looks for Stronger Cooperation with RoK in New Era

National

National

Vietnam News Today (May 14): US Businesses Affirm Long-Term Commitment to Vietnam

National

National

Vietnam News Today (May 13): Vietnam Maintains High Human Development Index Despite Global Slowdown

Popular article

National

National

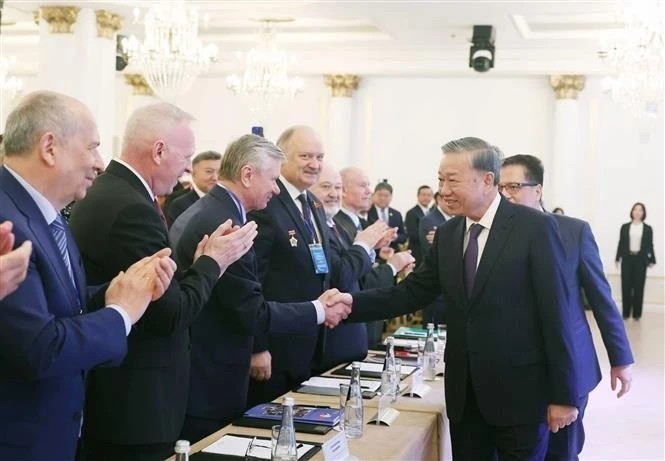

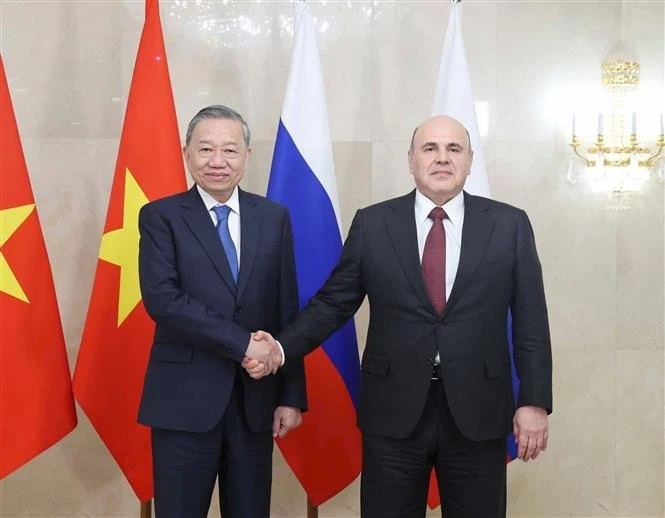

Vietnam News Today (May 12): Party General Secretary Meets With Russian Experts, Intellectuals

National

National

Vietnam News Today (May 11): Vietnam, Austria to Boost Cooperation in High-Tech Development, Innovation

National

National

Vietnam News Today (May 10): Vietnamese Peacekeepers Honored with UN Medal in South Sudan

National

National