India's quest for semiconductor self-reliance gets wings in 2024. Here's what to expect in 2025

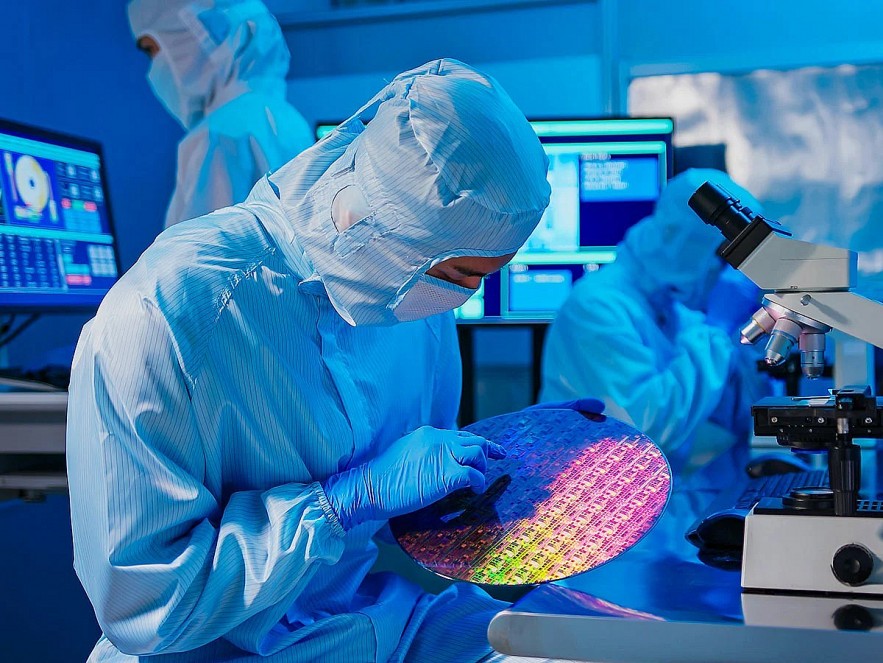

As the US and China compete to produce the world's most advanced chips, India has made a promising start by initiating construction of its semiconductor fabrication and packaging units. While India has taken the first steps, it needs to establish itself among the advanced players. Experts point out that as globalisation faces increasing pressures, geopolitics will play a crucial role in shaping trade and technology flows, making it essential for India to navigate these complexities effectively.

In 2024, several proposals were approved under the India Semiconductor Mission (ISM), with Gujarat attracting the most facilities. Tata Electronics is setting up a semiconductor fab facility in Dholera, investing Rs 91,526 crore to manufacture 28 nm chips. The company is also establishing an outsourced semiconductor assembly and test (OSAT) facility in Assam, with an outlay of Rs 27,120 crore. Other investments include CG Power's OSAT facility in Sanand, Gujarat (Rs 7,584 crore) and Kaynes Technology's OSAT facility in the same area (Rs 3,307 crore). All five semiconductor units will receive subsidies from central and state governments.

The Gujarat government launched the 'Gujarat Semiconductor Policy 2022-2027,' providing significant support to the sector. This policy complements the central government's financial assistance with an additional 40 percent subsidy for capital expenditure. Uttar Pradesh has also introduced the 'Uttar Pradesh Semiconductor Policy 2024' to foster a conducive environment for the industry.

According to Manish Gurwani, mission director of Gujarat State Electronics Mission, Micron's mini pioneer site is already operational, and construction on its greenfield project is expected to become operational by mid-2026. Meanwhile, Tata Electronics' project is expected to be completed by Q2 2027, and CG Semis' project by mid-2027. Kaynes Semicon's project construction work is expected to commence soon.

“The Gujarat government is proactively engaging with numerous suppliers and ecosystem partners associated with Tata Electronics, Micron, CG Semicon, and Kaynes Semicon to encourage the establishment of their units or offices within the state. In addition, efforts are ongoing to integrate local companies and international semiconductor firms into these supply chains,” Gurwani tells Forbes India.

The semiconductor manufacturing industry is fiercely competitive and characterised by high gestation periods. It is therefore critical to foster the right manufacturing ecosystem by drawing in and establishing ecosystem partners for these foundational investors. India's semiconductor consumption is projected to grow from $22 billion in 2019 to $64 billion by 2026 and $110 billion by 2030, accounting for approximately 10 percent of global demand.

“In 2024, I described the semiconductor industry as experiencing ‘unprecedented growth, opportunities, and challenges.’ Looking ahead to 2025, I believe these challenges will intensify due to global unpredictability, driven by diverse election outcomes and rising geopolitical complexities,” says Ajit Manocha, president and CEO of SEMI.

Despite these complexities, growth prospects remain strong, he adds. Manocha, who works closely with the Indian government, expresses confidence that the government will announce additional incentives for the semiconductor industry, as promised by Prime Minister Narendra Modi during Semicon India in September 2024. India is likely to follow the US model, with multiple states introducing friendly policies. “Gujarat is currently the focus area, but I'm optimistic that other states will follow suit, creating multiple hubs across the country,” Manocha says.

The ISM was launched in December 2021 with a financial outlay of Rs 76,000 crore to provide incentives for the development of a semiconductor and display ecosystem in India. It offers financial incentives to companies that set up semiconductor fabs, testing facilities, and design houses in India. The central government provides 50 percent fiscal support for capital expenditure on semiconductor fabs, display fabs, compound semiconductors, silicon photonics, sensors, and ATMP/OSAT facilities.

“We should expect a viable incentive with an adequate budgetary envelope in ISM 2.0,” says Anurag Awasthi, a policy specialist in semiconductors and critical electronics. The incentives are likely to be similar to those in previous enabling schemes, with some changes in certain segments already approved by the government.

There could be more incentives for advanced packaging. “At least two to three states are expected to announce well-defined policies within the next year, contributing to the semiconductor and fabless ecosystem. This will foster geographic diversity, competitiveness, and a pan-India availability of the talent pool for the future,” Awasthi adds.

Recommended

Economy

Economy