Samsung flies phone parts to Vietnam after coronavirus hits supply chain

|

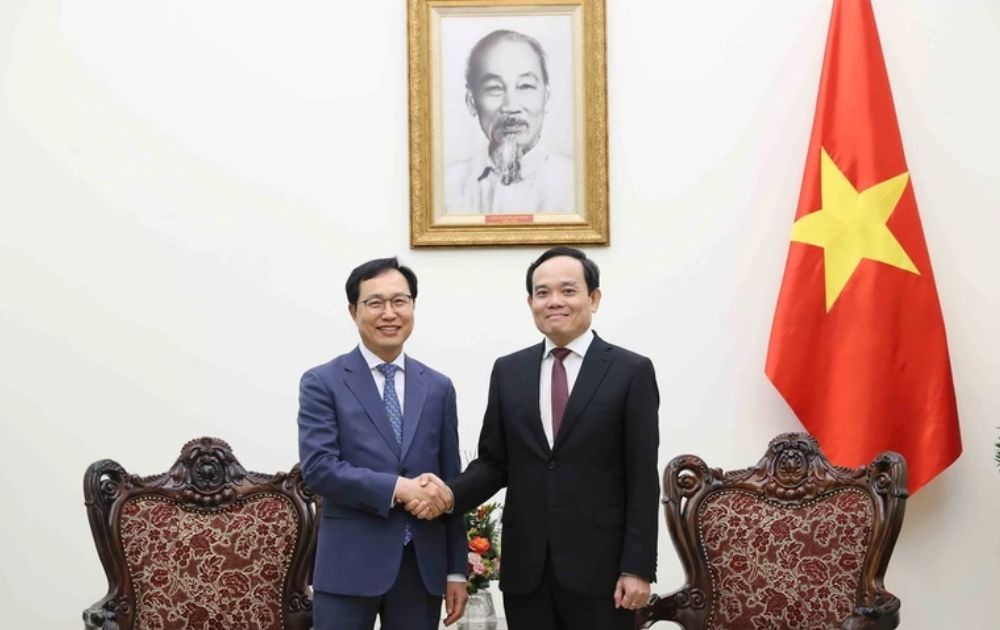

| Samsung produces nearly two-thirds of its phones, including its latest range, at plants in Vietnam. Photo: Bloomberg |

“The Vietnamese government is restricting the daily transport volume from China to Vietnam through land routes, but we’re coping with it by increasing parts supplies from China via planes and shipping,” said a person familiar with the situation.

Samsung launched its latest foldable smartphone and Galaxy S20 5G range last week in San Francisco.

“We are making our best effort to minimize the impact on our operations,” a Samsung spokesperson said, adding that production had not yet been slowed. The company declined to comment further.

Samsung, the world’s biggest smartphone maker, produces nearly two-thirds of its phones, including its latest range, at plants in Vietnam’s Bac Ninh and Thai Nguyen provinces.

But the coronavirus crisis has left Vietnam’s manufacturers, both local and foreign-owned, vulnerable in areas from electronics to textiles and footwear because many have supply chains that rely on China.

As factories in Vietnam resumed operations after the Tet lunar new year holiday, companies found the border with China closed or restricted for trade in both directions.

Vietnam and China have both taken steps since then to ease the flow of goods but Hanoi has imposed a quarantine on truck drivers returning from China, making some reluctant to drive there for fear of losing wages.

LG Electronics, another South Korean technology manufacturer which produces mostly low to mid-end smartphones in Vietnam, is facing similar supply disruptions. A spokesperson insisted the company has not yet faced inventory problems in Vietnam but is “considering various options” in case the crisis is prolonged.

Analysts warned, however, that because the companies source about 30 per cent of phone components from China, they could face serious problems with supplies of China-made cables, sockets, plugs as well as components for cameras.

“Their supply chains and logistics are in trouble because of the virus outbreak. If the problem persists for two more weeks, it may get out of control,” said Kim Young-woo, an analyst at SK Securities.

Hong Sun, vice-chairman of the Korea Chamber of Business in Vietnam, said many South Korean manufacturers carry inventory of only two to four weeks at their Vietnamese sites. “The fear is that if they don’t have enough parts, they can’t make the final product,” he said.

Vietnam has reported 16 cases of coronavirus so far, and has sealed off a part of Vinh Phuc province, northwest of Hanoi, where about 10,000 people live, after a cluster of infections there./.

In topics

Focus

Focus

Vietnam Covid-19 Updates (May 1): Daily Infections Fall to Nine-month Low of 5,109

Focus

Focus