Textiles firms launch emergency production of antibacterial masks

|

| Workers in a factory's mask production line in Thai Nguyen on February 6, 2020. Photo by VnExpress/Ngoc Thanh. |

At the beginning of last week, Toan, an employee of the Dong Xuan Knitting Company in the northern province of Hung Yen, was transferred to an antibacterial cloth production line. His company had begun making this new product following the novel coronavirus (2019-nCoV) outbreak.

Toan and her colleagues now try to use their afternoon break to produce more masks in order to meet the amount needed each day as well as earn some overtime income.

"Most of us are doing an extra half-shift of overtime every day. Because we make more money, everyone is happy and trying to take advantage of the situation," he said.

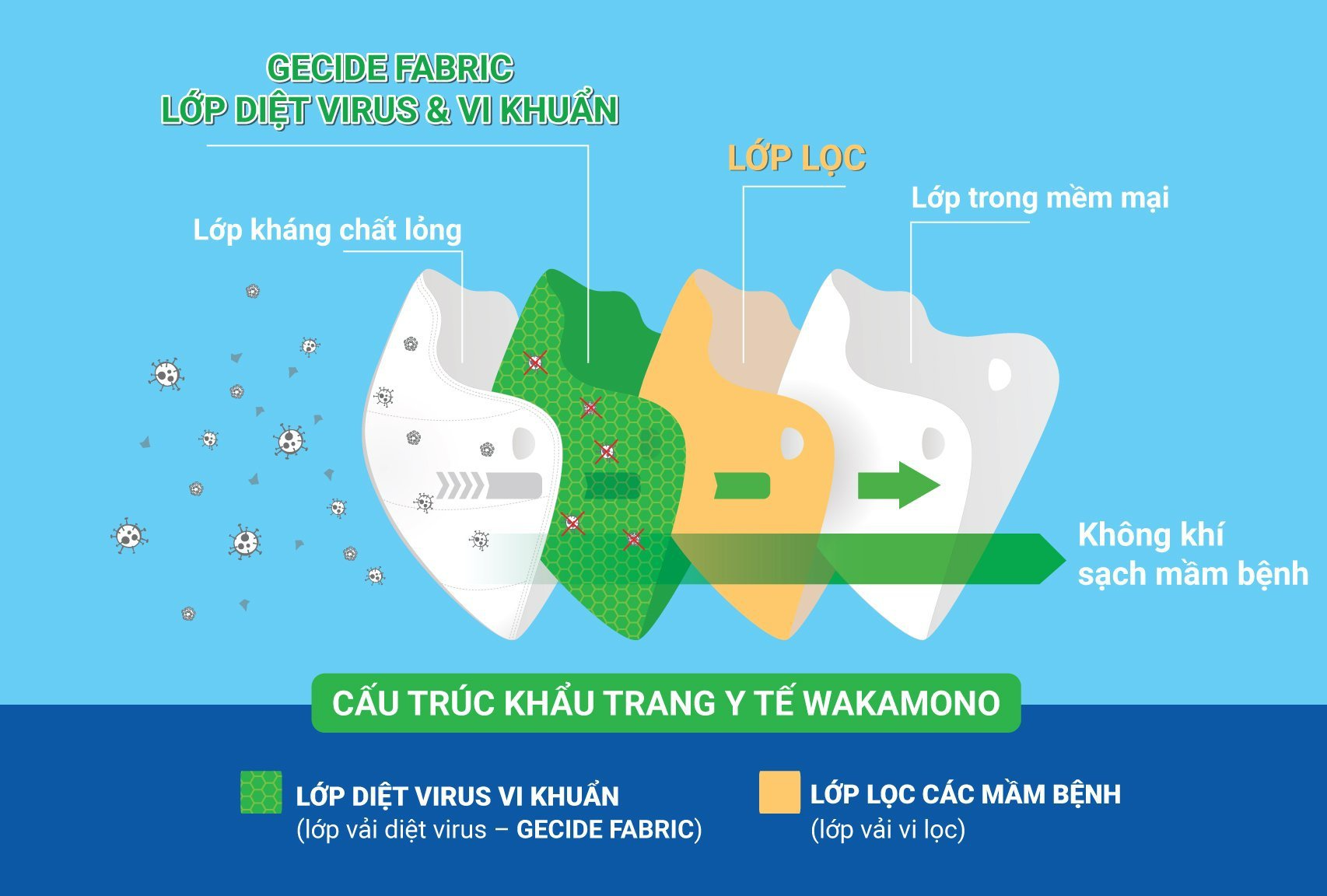

The Dong Xuan company has set up a similar antibacterial cloth production line in one of its factories in Hanoi. Its director Tran Viet said although the company has not worked in medical supplies before, it was applying Japanese technology to produce antibacterial fabric given the current scarcity of masks.

Viet estimated that the company now produces 7-8 tons of anti-bacterial fabric every day, enough for Dong Xuan and its partners to produce up to 300,000 masks each day.

"We are working every hour to improve productivity, so after it stabilizes, we will see if we can serve orders in other epidemic affected areas if needed," Viet said.

Le Tien Luong, general director of The Vietnam National Textile and Garment Group (Vinatex), one of the largest textile makers in Vietnam, said the company needed about three to four days to rearrange production lines, train workers in new technology, as well as transfer designs from affiliate companies to make masks, which was a new product to the group.

TNG, a company based in northern Thai Nguyen Province specializing in producing garments and fashion for export, has also joined the emergency production of masks, using nano- fabric.

The company was able to kick off production of antibacterial nano masks just three days after it submitted designs and standards for approval from the Ministry of Health, said TNG chairman Nguyen Van Hoi.

|

"Raw materials used to produce clothes and production lines are now prioritized for making masks. Soon 2 million masks will be completed and released to the market to help ease shortages, and soon after, TNG will be able to mass produce them," Hoi said.

Currently, the enterprise has increased working hours and allocated as many workers as possible to ensure it rolls out 20,000 masks a day. TNG said it will also work with the Thai Nguyen Department of Health to give out one million free masks to people.

Bui The Kich, general director of the Dong Nai Garment Corporation, said his enterprise has also been producing anti-bacterial fabric at maximum capacity. The company now produces around 10-15 tons of the fabric every day, and one kilogram of it is used to make approximately 300 disposable anti-bacterial masks.

However, he pointed out that the Health Ministry has not issued standards and regulations for the anti-bacterial cloth masks. It needs to do so as soon as possible so that "users can trust the products," Hoi said.

Truong Thanh Hoai, head of the Department of Industry under the Ministry of Industry and Trade, said producing 10 million antibacterial masks every day, as requested by the Ministry of Health’s request, required 400 tons of antibacterial fabric and enterprises working at full capacity.

Vietnam officially declared the nCoV outbreak an epidemic on February 1. Out of the 15 confirmed infection cases so far, three have been discharged from hospitals: a Nha Trang hotel receptionist, a Chinese man from Wuhan, and one of the workers who returned from Wuhan.

The global death toll of the epidemic has reached over 1,000 – one each in the Philippines and Hong Kong, and the remaining in mainland China./.

In topics

Focus

Focus

Vietnam Covid-19 Updates (May 1): Daily Infections Fall to Nine-month Low of 5,109

Focus

Focus

Vietnam Covid-19 Updates (April 29): 7,100 Cases, 79,000 Recoveries Reported

Recommended

Economy

Economy